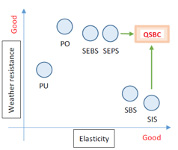

Zeon has developed a new material it is calling Quintac Styrene Block Copolymer. The new polymer, also known as QSBC, offers a unique combination of properties…the elasticity of SIS (styrene-isoprene-styrene) AND the heat resistance characteristics typical of SEPS (styrene-ethylene-propylene-styrene) or SEBS (Styrene-ethylene-butylene-styrene). Zeon’s ability to control the polymer structure at the nano level is key to enabling design of this novel TPE.

Seeking Application Partners

Zeon is seeking compounders and end users interested in developing products using QSBC.

QSBC is currently at the advanced product development stage, and Zeon is seeking input from professionals in various markets on application requirements and fit.

Key Technology Features and Advantages

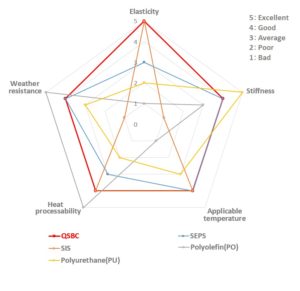

- High stiffness and high elasticity

- Greater flexibility than polyolefin elastomer

- Simplified processing (can be put directly into extruder without premixing) thus saving energy

- Improved resilience & durability over SEPS

- Stable up to 170°C with high moisture resistance

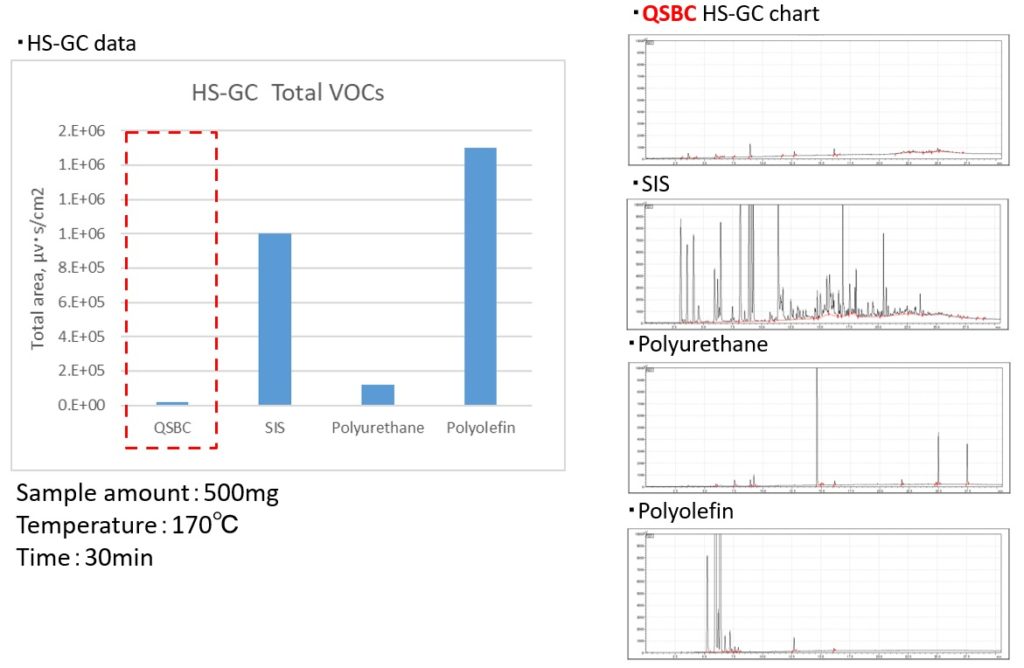

- Low VOC level, especially compared to SIS and polyolefin

- Lower odor than SIS, polyurethane, and polyolefin

- Dissolves readily in oil (comparable to traditional SEPS)

- Excellent anti-oil migration

QSBC is heat stable up to 170°C with high moisture resistance. Its low odor and virtually undetectable VOCs make it a potential fit as a polymer performance additive for hot-melt pressure sensitive adhesives and sealants used in automotive interiors, consumer goods, and medical products. QSBC can also be used as an excellent impact modifier or toughener for clear polypropylene (PP).

QSBC maintains resiliency, even when quite thin, differentiating it from other functional materials in the market. Utilizing QSBC as an alternative to other materials used to increasing product resilience could reduce weight of many end products.

QSBC when used as a modifier for thermo-polymers can be mixed in amounts similar to when adding SEBS.

Zeon believes manufacturers seeking to improve processability/workability will want to evaluate QSBC as it simplifies processing and mixability of resins.

Potential Applications

- QSBC alone:

- High temperature pressure sensitive adhesive

- High temperature resistant films and sheets

- Molded parts

- QSBC in blends or alloys with other thermoplastic elastomers:

- Components for suspensions, engine mounts

- Silentblocks for cars, motorcycles, scooters and mountain bikes

- Automobile interior parts (imparts impact resistance to plastic parts)

- Softener for ABS

- Electronic equipment housing

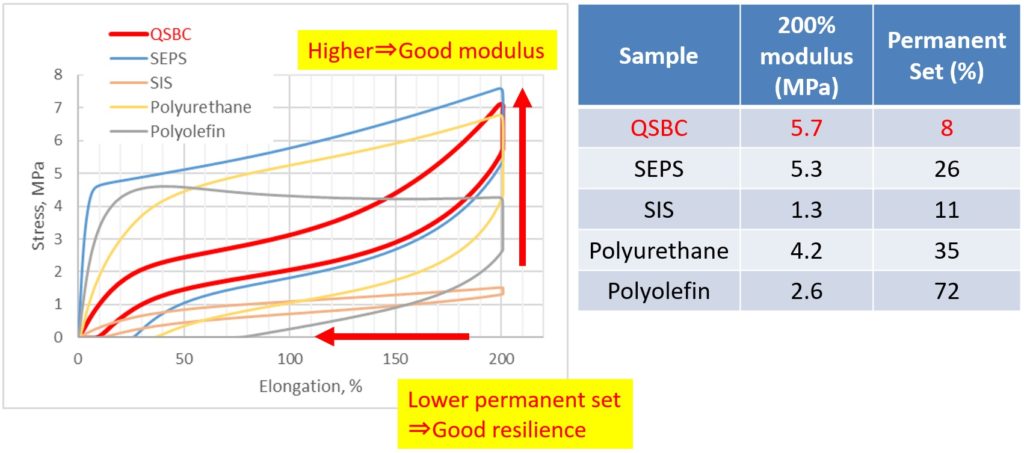

Elasticity and Stiffness

Zeon QSBC has a permanent set of 8%, a value much lower than conventional SEPS, polyurethane and polyolefin and on par with conventional SIS, as illustrated in the hysteresis data below. Permanent set is the amount by which a material stressed beyond its elastic limit fails to return to its original size or shape when the load is removed. By controlling the microphase-separated structure, it is possible to achieve the same resilience (lower permanent set) as SIS even in a high stress region (higher modulus).

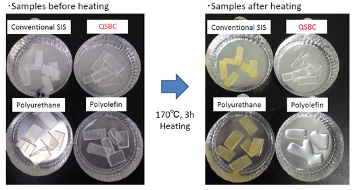

High Temperature Performance

QSBC maintains its form and transparency at temperatures up to 170° C for 3 hours, as seen below. Most other TPEs start to melt, deform or discolor. Additionally, its low VOC and low odor characteristics, relevant at elevated temperatures, are comparable to SEPS products on the market, and much lower than polyurethane olefins.

Low VOCs as an Indicator of Weather Resistance

As materials decompose they release VOCs and odors. So low VOC and low odor are one of the indicators that a material has high weather resistance. Furthermore, materials with low VOCs and low odors are desirable for use in the automotive (interior parts), medical and adhesive industries. No odor is detected when QSBC is heated at 170°C for 30 minutes. No VOC components are detectable either. In comparison, conventional SIS, polyurethane and polyolefin begin to decompose and generator VOCs and odors during the same test, as illustrated below.

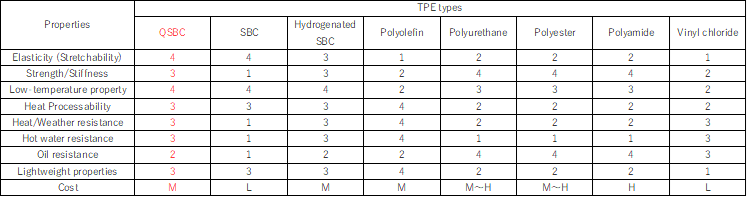

Comparison Against Other Thermoplastic Elastomers

NOTES:

- SBC (styrene block polymer) refers to SIS and SBS

- Hydrogenated SBC refers to SEPS and SEBS

Technology Development Status and Owner

Status: Zeon’s QSBC is currently at the advanced product development stage. Zeon is seeking input on application requirements and fit from compounders and end users interested in developing products in various markets using QSBC. Small quantity samples will be available in early 2021. Additional information is available upon request.

Owner: ZEON CORPORATION is a $3.3B, 3,300-person chemical company focused on specialty elastomers, polymers, and specialty chemicals founded in 1950. The company produces a variety of products including high nitrile rubber that can be used in strong cements and adhesives, acrylonitrile butadiene copolymer latex, resins and other rubber additives.