This project is no longer open for submissions.

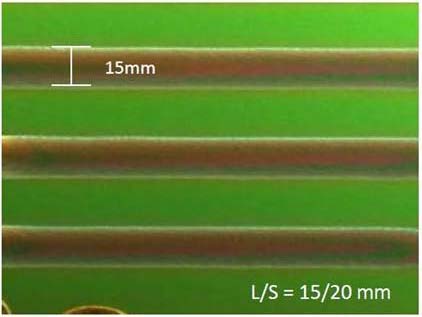

EPRIMA® AL-X6 is a thermally curable insulating coating that is based on a fluorinated polymer. The surface wettability of the highly transparent dielectric coating can be controlled by exposure to UV, enabling accurate ink-wettable alignment guides to be created in the coating when printing conductive inkjet inks such as those containing copper or silver. Without Al-X6, conductive inkjet lines can print down to 30-40 microns. With AL-X6, discrete conductive inkjet lines of 15 microns (on 20-micron separation) have been achieved without

spreading or bulging.

The degree of wettability is highly controllable, enabling biochips where a varying gradient of wettability draws liquids through the chip. AL-X6 is highly transparent compared to polyimide, and requires lower curing temperatures. Heat loads to the other biochip materials can therefore be much lower. AL-X6 is extremely flexible. Its flexibility and mechanical properties provide

application advantages over epoxy.

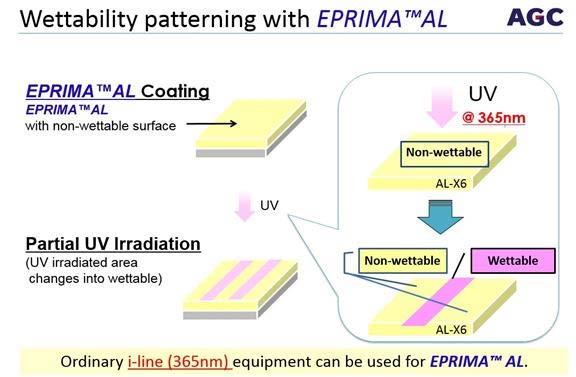

The naturally hydrophobic surface becomes wettable when exposed to common i-Line 365nm UV. This is much less expensive than existing methods of wettability patterning, which require UV with a λ (lambda) of less than 300nm and special optical components. No additional equipment is required to use AL-X6.

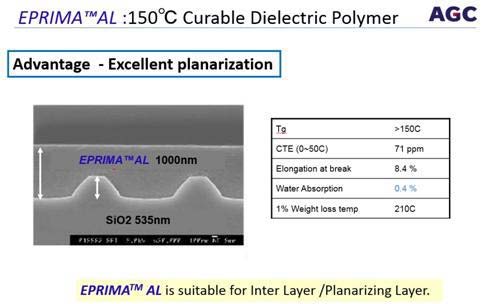

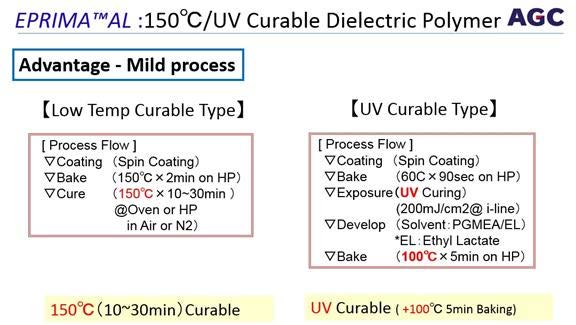

The coating already has been tried successfully as a dielectric material for OTFT (Organic Thin-Film Transistors) and as a pattern-assist material for metal inks. Manufacturing processes using AL-X6 take place at lower temperatures than polyimide — AL-X6 cures at 150°C, and at even lower temperatures and more

quickly if UV is used. It is thermally resistant to ~200°C, offers excellent resistance and planarizing abilities.

便益情報の要約 (Benefits Summary)

EPRIMA® AL-X6 provides a fluorinated polymer coating suitable for use as a dielectric and wettable pattern-assist material.

It offers excellent planarization for electronic and semiconductor applications. o Transparency: Transmittance is 99% at 400nm – visible light lies between 380nm and 700nm, so EPRIMA® AL-X6 is suitable for optical applications.

The material offers low temperature curing, so heat load on substrates may be lessened.

Unique functions can be added to the material, for example: UV exposure creates wettable areas on the surface of the material, enabling its use as an alignment aid for inkjet deposition of conductive inks. Lines of 15 microns have been achieved. A gradient exposure to UV can create biochips that draw liquid through the chip based on the gradient.

UV-curable EPRIMA® AL-X6 is also available.

開発情報の要約 (Development Summary)

The technology has progressed to the prototype stage. EPRIMA® AL- X6 has been used as a dielectric coating and gate insulator in OTFT (Organic Thin-Film Transistors) and as a pattern-assist material for metal inks.

便益情報 (Technology Benefits Description)

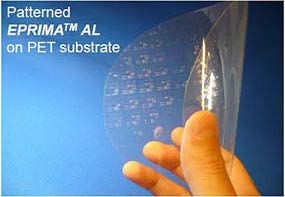

Figure 1. EPRIMA® AL-X6 is a fluorinated polymer coating. It has already been tried successfully as a reliable gate insulator in organic electronic devices.

Figure 1

Figure 2 indicates basic electrical properties of EPRIMA® AL-X6. It has a high breakdown voltage and low

leakage current.

Figure 2

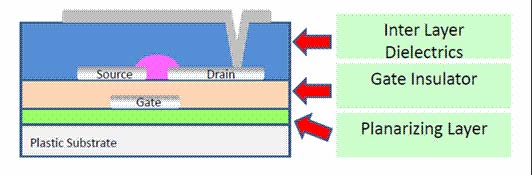

Figure 3. EPRIMA® AL-X6 offers excellent planarizing abilities.

Figure 3

Figure 4

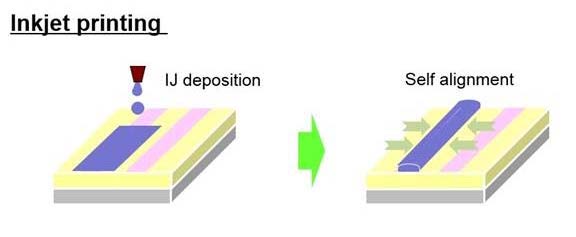

As an alignment aid, EPRIMA® AL-X6 has achieved line widths of 15 microns (on spacing of 20 microns)

with inkjet-printed metal inks.

Figure 5

Wettability can be controlled by i-Line 365nm UV, enabling use in biochips where the wettability gradient can

draw liquid through the chip.

Figure 6

Figure 7. EPRIMA® AL-X6 offers low curing temperatures and UV-curing options.

Figure 7

The material is thermally resistant to 200°C, and transparent. Transmittance is 99% at 400nm — visible light lies between 380nm and 700nm, so EPRIMA® AL- X 6 is suitable for optical applications.

技術の新規性 (Technology Differentiation and Uniqueness)

EPRIMA® AL- X6 offers low-temperature manufacturing (only 150°C compared to curing polyimide at 200°C). Cures quickly.

Widely available i-Line 365nm UV equipment can create wettable patterns on the surface of the EPRIMA® AL- X6 coating. Other technologies in use require UV with a λ (lambda) of less than 300nm and special optical components.

開発段階 (Development Stage)

Commercialization

開発情報の要約 (Development Status Summary)

The technology has progressed to the prototype stage. EPRIMA® AL- X6 has been used as a dielectric coating and gate insulator in OTFT (Organic Thin-Film Transistors) and as a pattern-assist material for metal inks.

技術の掲載者 (Technology Provided By)

ASAHI GLASS CO., LTD.

関連するコンピタンス (Related Competency)

The AGC Group has built up various competitive advantages through business activities spanning over a century, including expertise and technologies in diverse fields such as glass, chemicals, and ceramics, and a global network covering a wide range of industries, from building materials and automobiles to electronics. http://www.agc.com/english/index.html

掲載技術の移転状況 (Provider Transaction Status)

Has not engaged in Introductions

掲載者が希望する契約形態 (Collaboration Type Sought)

For Sale