Overview:

A yet2 client, Zeon Corporation, is seeking feedback from compounders and molding manufacturers as to the usefulness of a highly stretchable, resilient elastomer (mSIS), which exibits a 95% recovery from ultra-high tensile strain. It could be an additive or modifier. Possible applications could include robot skin, artificial muscle, highly stretchable films, tackifier, and polymer modifier to impart elasticity and stress relaxation properties to ABS, urethane, acrylic, and other plastics.

mSIS is a modified version of the SIS (styrene-isoprene-styrene) block copolymer, exhibiting improved resiliency compared to other thermoplastic elastomer block copolymers like conventional SIS and SBS. When conventional SIS is stretched with a strain of 500%, its strain recovery is approximately 30 to 40%, and when stretched with a strain of 1000%, its strain recovery is approximately 50 to 60%. However, this modified version of SIS (mSIS) can be stretched to a strain of 1300% with a subsequent 95% strain recovery.

In addition to high strain capacity and strain recovery following large deformation, mSIS has a higher tensile strength than unmodified SIS and exhibits improved stress relaxation behavior under sustained strain loading.

While conventional SIS is not easily mixed with polar materials such as urethane, ABS or acrylics, mSIS mixes well with them, making it a suitable modifier for such materials to impart properties such as increased elongation to break, strain recovery rate, tensile strength, stress relaxation capacity, toughness, and impact resistance. Some examples are as follows: adding mSIS will improve the impact resistance of ABS resin; adding mSIS to urethane will suppress brittleness.

Key Features:

- High stretchability: up to 1300% tensile strain before breaking

- Excellent strain recovery: 95% after 48 hours (much higher than SBS and SEBS)

- High tensile strength compared to other thermoplastic elastomers

- Robust stress relaxation behavior and durability under sustained strain

- Thermoplastic, allowing flexibility in processing

- Versatile modifier: easily mixed with polar materials such as ABS, urethane, acrylic

- Dissolves in hydrocarbon solvents

- Can be made nearly transparent

- Estimated price: under $8/kg (assuming exchange rate of Y118 = $1)

Technology:

mSIS is a modified SIS produced through Zeon’s proprietary technology which introduces succinic anhydride into the isoprene monomer unit of SIS, thereby creating functional groups with hydrogen bonding ability.

After being subjected to high stress and strain, all of the hydrogen bonds (a pair of two functional groups of L shaped blocks) are reinitiated or re-associated in the recovery process. Strength and stiffness are almost entirely recovered after 48 hours.

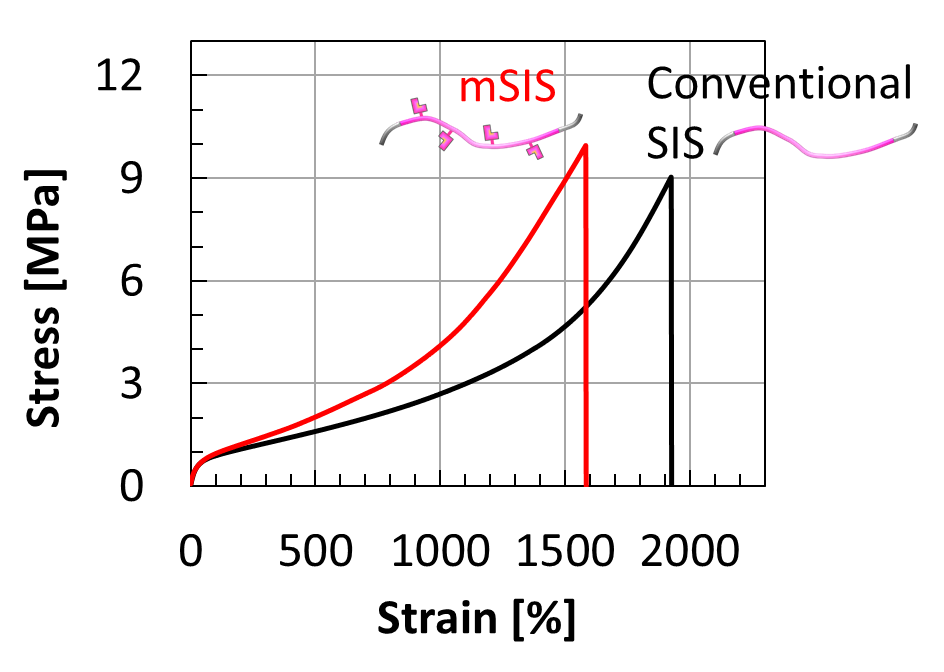

Compared with conventional SIS, the tensile stress of mSIS is higher at the same strain due to the hydrogen bonding functional group.

Comparison of stress-strain curves of SIS and mSIS

Comparison of stress-strain curves of SIS and mSIS

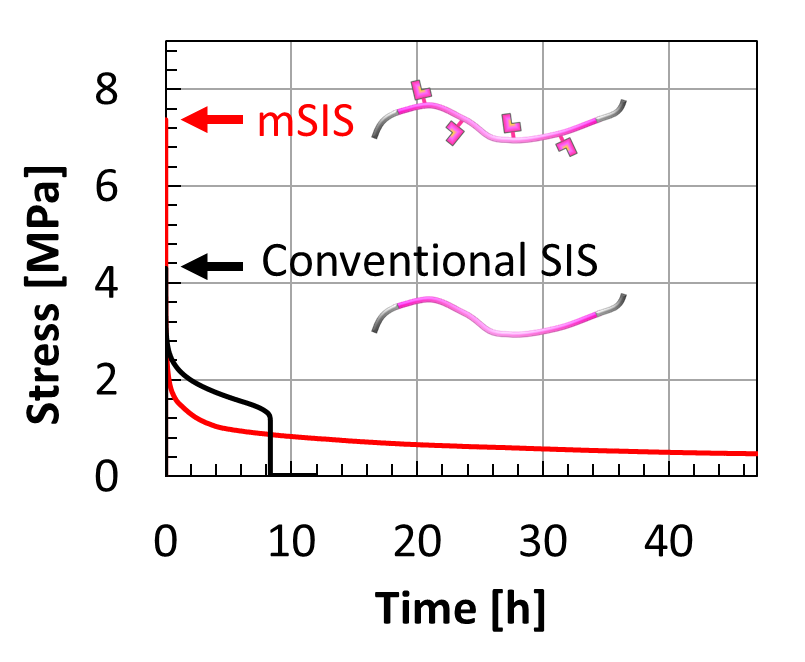

mSIS’s most notable feature is its robustness under large deformation. mSIS does not break easily even when it is elongated with a large strain for a long period of time. For instance, when SIS and mSIS are held at 1300% strain, SIS breaks in 8.3 hours after elongation, whereas mSIS does not break even after 47 hours.

Comparison of stress relaxation curves of SIS and mSIS. Arrows represent the maximum stress.

mSIS elongated with a strain of 1300% exhibits remarkable strain recovery behavior after stress is removed.

Demonstration of mSIS strain capacity and strain recovery

Company Overview:

Zeon Corporation is a $3.3B, 3,300-person chemical company focused on specialty elastomers, polymers, and specialty chemicals founded in 1950. The company produces a variety of products including high nitrile rubber that can be used in strong cements and adhesives, acrylonitrile butadiene copolymer latex, resins and other rubber additives.