yet2 seeks to license, on behalf of Janssen PMP, its novel, developmental, water-repellent, fluor-free, super-hydrophobic (FF/SH) coatings technology. Two unique value propositions of these coatings are that they offer:

- Far superior performance to widely-used paraffin wood coatings

- Competitive performance to fluorine-based coatings at a considerable cost advantage

We anticipate that existing customers and non-customers with positions in Janssen’s core wood protection, anti-fouling and industrial & health/hygiene microbial control markets will have interest. In addition, the technology and formulations offer benefits across a broad range of application spaces, both industrial and consumer, including: water repellent paints, textiles & apparel, concrete, stone & brick, marine coatings and ‘consumer/aftermarket waterproofing.’ Thus, coatings companies and large-scale users of protective coatings will want to consider securing this technology.

Technology Development, Description and Features

Development:

The subject coatings emerged from research at Janssen to formulate concentrates that would be added to wood preservatives to render them hydrophobic. What resulted were a ready-to-use treatment/coating formulations with super-hydrophobic properties, which, in addition to wood, have proven to be useful in protecting textiles, minerals, and virtually any water-absorbing surfaces.

As Janssen’s business is in concentrates, it has opted to offer the technology to companies having greater means to produce and sell the formulated products.

Description:

Water-repellent FF/SH coatings are formulations of (1) metal C3-8 alkyloxides… e.gs. tetrabutyl ortho titanate (TBOT) or aluminum isopropoxide (AlIP) and (2) alkyl ketene dimer (AKD), with (3) a combination UV-absorber/radical scavenger UV protection system. While initial focus had been on TBOT-AKD combination formulations, later developments demonstrated superior performance of AlIP-AKD formulations.

Features:

- Suitable for wood, textile, paper, concrete…most surfaces

- Brushes on easily and evenly as an extremely thin (<10 mils) and transparent film

- Can be applied as a one application coating

- Super-hydrophobic surface, excellent water beading effect…contact angle of 150o or greater

- Water-repellent, but not water-tight … thus, breathable*

- Creates a slip resistant surface

- Long service-life compared with other water sealers

- Formulated with UV-protection

- Uses common, broadly available raw materials

- Easy to manufacture with no special equipment needed

- Patent protected (pending)

*Moisture and oxygen vapor transmission rates have not been tested.

IP Portfolio

Janssen has filed for composition of matter patents (published application WO2017/042120), filed as PCT/EPO & EP application targeted toward Australia, Canada, China, India, Japan, New Zealand, Russia and USA/EU (country split pending).

Technical Development Stage

The company has performed some considerable development and testing. In addition to the information found in the patent applications, Janssen has generated more than 60 documents containing data about the material and its performance characteristics.

- Formulations have yet to be fully optimized

- Currently, only solvent-based formulations have been developed

- The formulations are available in ready-to-use form only and not as concentrates.

Market Development Stage

Water-repellent FF/SH coatings have not been produced or sold commercially. Janssen believes that are likely to be very few if any challenges producing at commercial scale. The coatings are available in sample quantities.

Partnership Opportunities

Janssen is pursuing the strategy of licensing rights to manufacture, sell & use their patent-pending technology. The company is open to a variety of deal types/structures. The ideal licensee will be a single, company capable of completing the development and commercializing the technology across markets. Yet, licenses (including exclusive licenses, potentially) specific to one or more markets, applications and/or regions, are also considered viable.

Licensees can expect to receive excellent support from technologists familiar with the materials and required processes, learning nuances of formulation variables and performance. Janssen has excellent experience, know-how and credibility in microbial control and is knowledgeable about the qualitative issues related to wood products used in the exterior (outside) environment: discoloration, organisms, shrinking, warping, rotting.

Company Overview

Janssen PMP (Beerse, Belgium) is a division of Janssen Pharmaceutica NV, a wholly-owned subsidiary of Johnson & Johnson, a $76 billion (US), 134,000-person consumer products, pharmaceutical and medical device company. Janssen is focused on high performance treatments and technology to prevent degradation in two primary pillars of business: microbial control (antifouling, wood protection, industrial applications & hygiene and healthcare) and post-harvest (vegetable and fruit protection).

Select excerpts from supporting Test Data

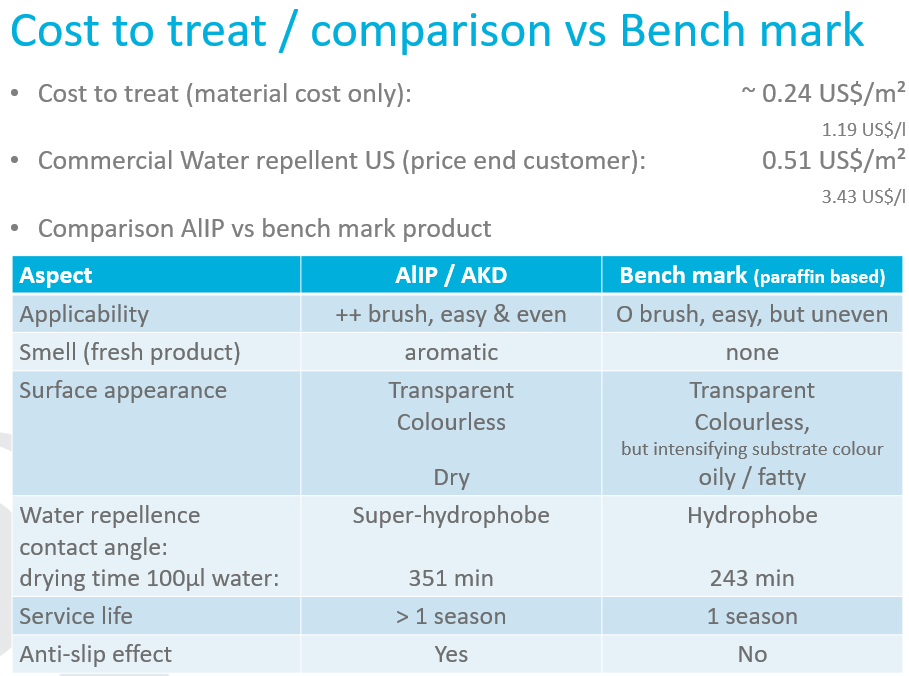

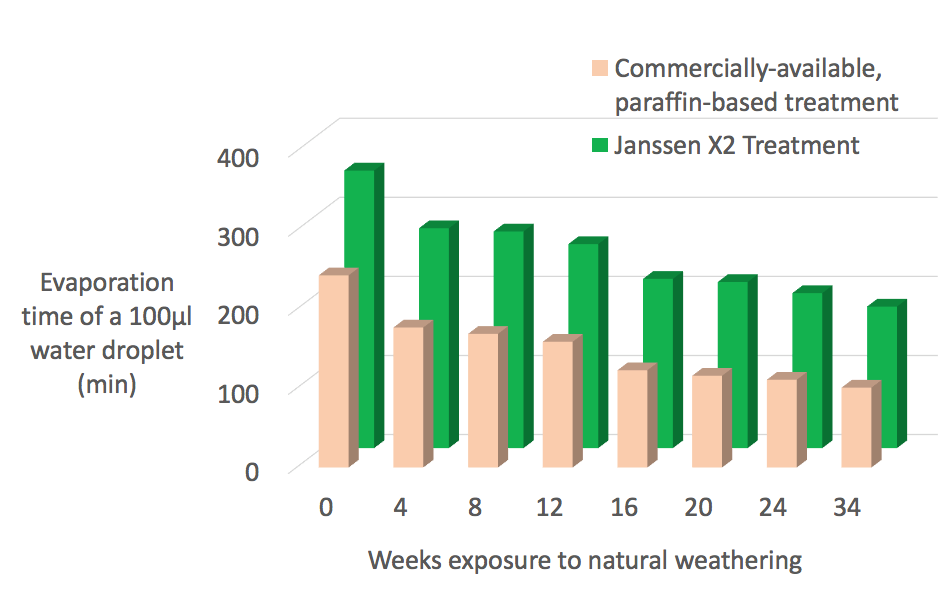

FIGURE 1

Evaporation Rate of Water Droplets on Wood Exposed to Natural Weathering

Figure 1: Janssen X2, the latest generation formulation developed, showed an almost 60% longer evaporation time compared with a commercially-available, paraffin-based “water sealing” treatment when first applied. The relative evaporation time grew to almost 80% longer than the commercially-available treatment after weeks of exposure to natural weathering.

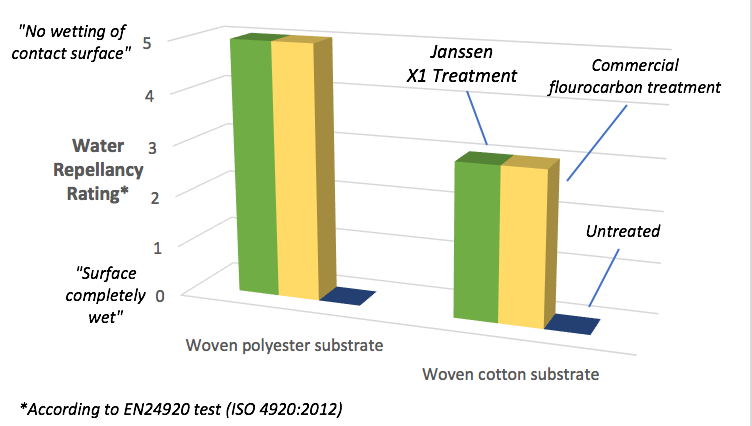

FIGURE 2

Water Repellence of Janssen X1 Compared with a Commercial Fluorocarbon Treatment on Two Substrates

Figure 2: Janssen X1 demonstrated equivalent water repellence to a commercial fluorocarbon treatment on woven polyester and woven cotton substrates.

FIGURE 3

Water Repellence of Janssen X1 on a Broad Spectrum of Substrates

Figure 3: Janssen X1 outperformed a monolithic Teflon surface reference sample when applied to paper, nonwoven, absorbent cotton and cotton cloth and admirably, if not as well as the Teflon surface when applied to gypsum, suede and floor tile. Left untreated, each of these substrates scored as 0.01 or less on this chart, highlighting the dramatic effect of the X1 treatment.

FIGURE 4