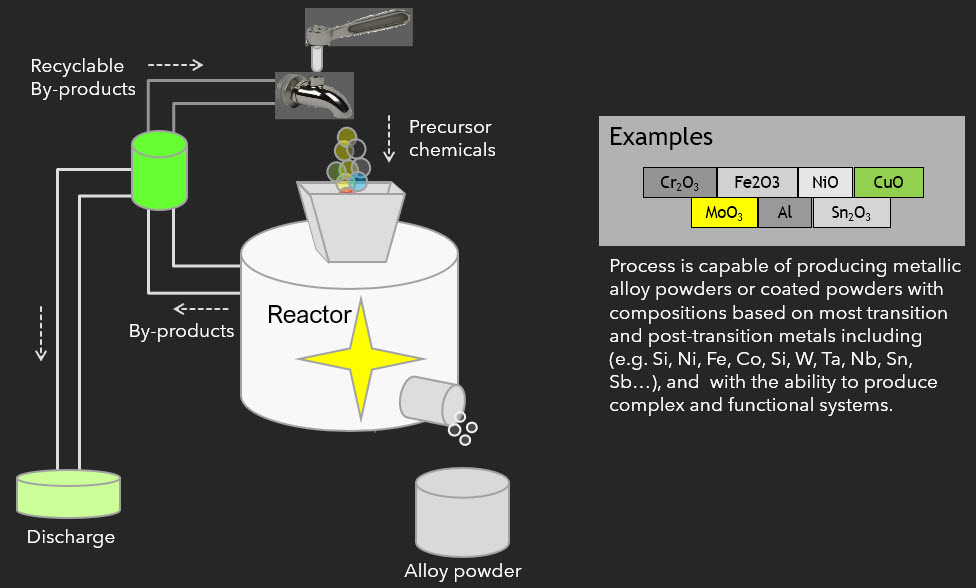

Direct Production of Metal Alloy Powders

Our client has developed and patented a first-in-world, integrated, one-step process for producing metallic alloy powders, catalysts and metallic pigments, from low-cost chemicals.

The company seeks additional commercialization partners through licensing, co-development, and manufacturing arrangements.

The technology enables the reduction of metal oxides and chlorides at low temperatures for more than two dozen different metals, including Fe, Co, Ni, Si, Ni, Cr, Cu, Zn, Al, V, Nb, Mo, Ru, Rh, Pd, Ag, Cd, Ta, W, Re, Os, Pt, Sn, Pb, Sb and Bi.

The alloy powders, immediate precursors to catalysts, can be prepared using any combination of metal chlorides and may be doped with almost any other metal. Resulting products include metal powders and nanopowders, superalloy powder, metal aluminides and functional, metal- Al2O3 systems (including nano dispersion of Al2O3 and complex systems (E.g., Si-Ag-Sn).

Summary of Comparative Value Proposition

LOW COST

- Capital: Atmospheric pressure operation; simple equipment with moderate process conditions

- Operations: Elegant, one-step, fully automated production; limited labor input; high yields

GREEN

- Low-temperature, exothermic reactions; process requires minimal energy and generates minimal waste. Greater than 95% reduction in CO2 emitted in production

ROBUST

- One-step process: Minimal process complexity enabling consistently high-quality products A product “designer’s dream”: uniquely suited for development and low-cost production of a customizable range of morphologies/compositions

READY

- Full proof-of-concept; system demonstrated for multiple metals (e.g., Nickel Si…)

PROTECTED

- Patent-protected and know-how secured

Related Projects

- Technology for Non-destructive Inspection Inside Concrete Structures

- Sustainably Made Hydrocarbons and Other Specific Chemicals

- Cable Sealing System, Material, or Technology That is Easy to Remove and Reinstall