Background

Tokyo Electric Power Company Holdings, Inc. (TEPCO) needs a technology to seal against water for openings/ducts for cables that run into a building from the outside. Appropriate solutions can involve sealing materials (filler, sealant, resin, and gel) or cable pit systems. The system has to be removable to allow for the future replacement of deteriorated cables.

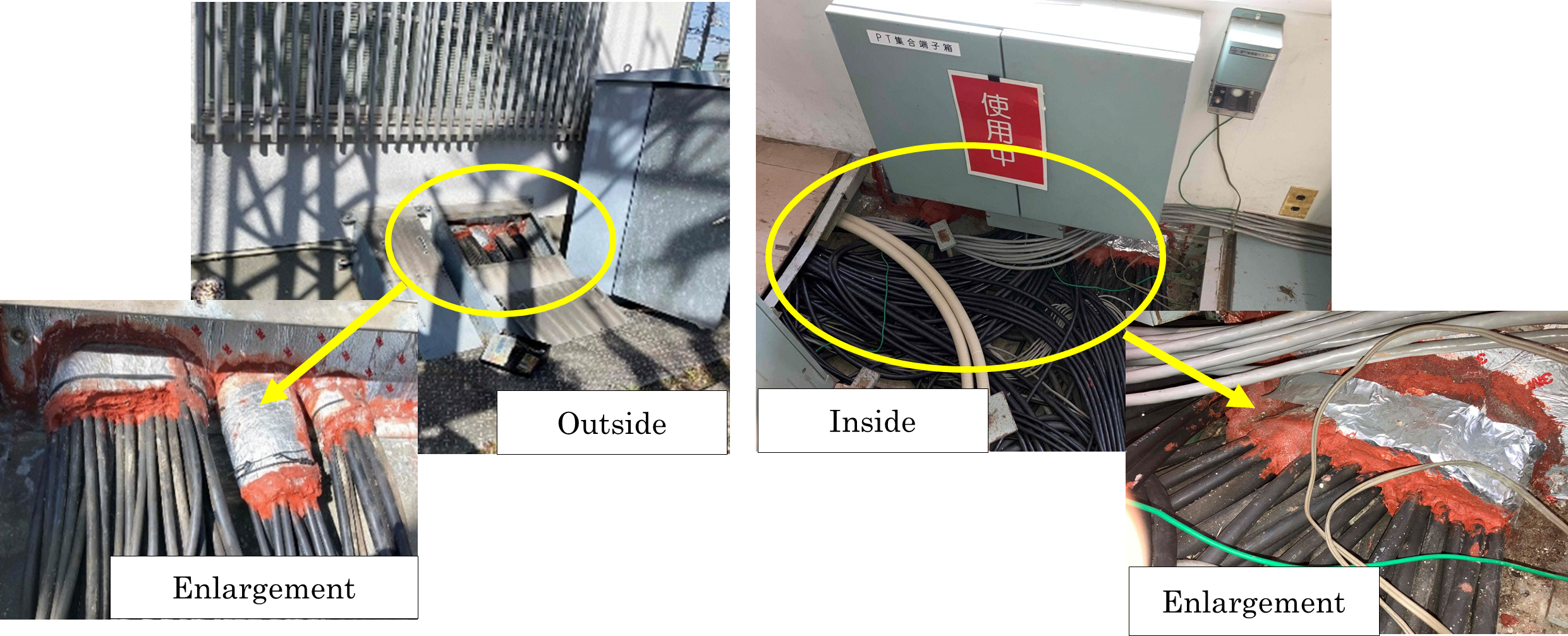

Currently, cable pits are sealed with a type of rubber or with polyurethane foam. These materials seal well but do not make it easy to replace or reinstall cables. TEPCO is seeking either an easy-to-remove material that seals populated cable pits well or a sealing system (cable pit) that allows for cable replacement.

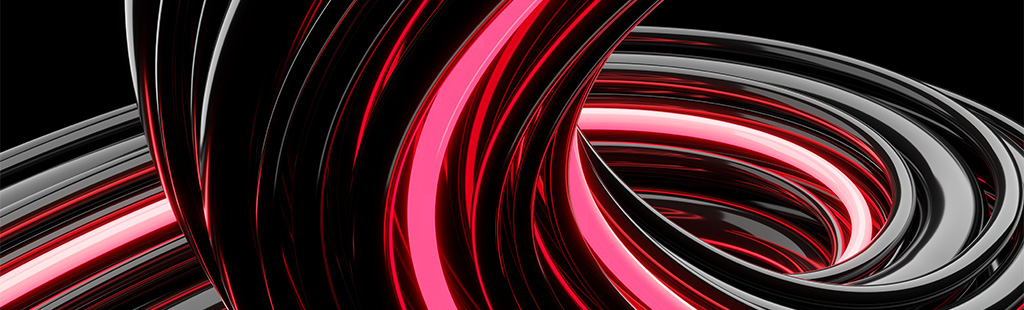

Examples of Current Cable Pit Sealing

Summary of Technology of Interest

- Sufficient sealing performance for narrow gaps, such as between cables in a cable pit (sealant) and

easy to remove (sealant) - Hazardless

- Easy to add/retrofit and remove cables (sealing pit/system)

Requirements:

- Sufficient sealing performance for narrow gaps, such as between cables in a cable pit (sealant)

- Easy to remove (sealant)

- Easy to add/retrofit and remove cables (sealing pit/system)

- Leakage resistance of water > 20 kpa

- Hazardless

Desired qualities:

- Applicable to narrow gaps between cables (in the current situation, openings are often crowded with

cables and high-viscosity sealants do not spread across them) - Harmless to cable covers (insulation), thermally stable, and good at dissipating heat

- Flame resistant

- Applicable in a ditch where the only open space is above the cable pit, not to its side (see the first

example photo) - Applicable to existing openings for cables (allow for the retrofit of new cables or re-routing)

Information Requested for Technical Evaluation:

- Construction time needed

- Size of opening for cables (e.g. 100 cm x 100 cm)

- Thickness of the wall (e.g. >5 cm)

- Applicable cable diameter (e.g. 2 – 5cm)

- Price

Stage of Development:

Solutions do not necessarily have to be in the market at this time, but samples must be available for

evaluation and the product should be ready for practical use within six months to a year.

Related Tech Needs:

- Seeking: Technology for Removing Debris From Power Lines

- Seeking: Debris Mitigation and Removal for Dams

- Seeking: Plastic Pollution Offsetting and Ocean Plastic Removal