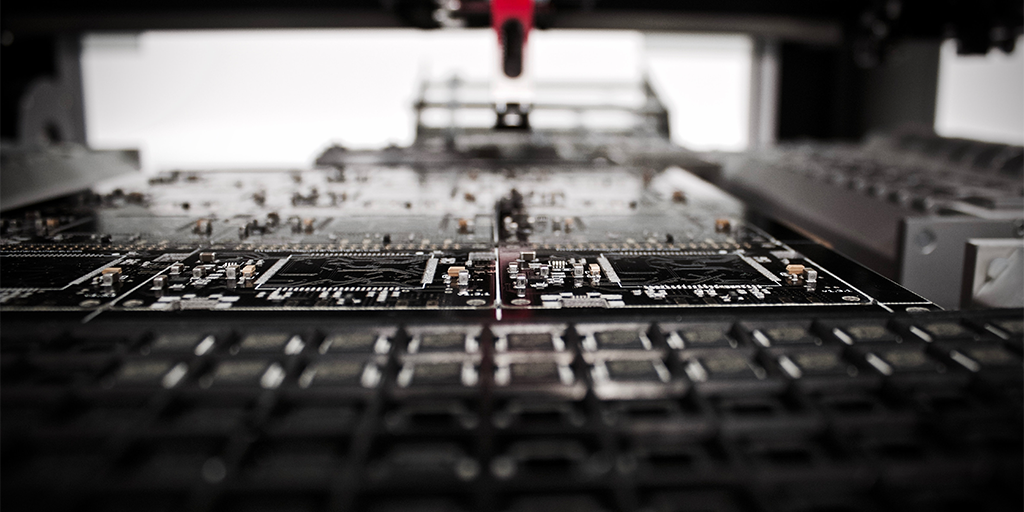

An optical devices manufacturer seeks rapid assembly technology to develop more efficient manufacturing capabilities for its optical component businesses.

Background

Currently, assembly of optical devices is time consuming. Active alignment technology is used to adjust the optical axis, alignment is performed while monitoring the light intensity, and components are bonded and fixed using UV adhesive.

In the future, the number of channels is increasing due to the speedup of optical devices, and they are looking for improved process technology to reduce assembly time.

Constraints

Components will:

- Be able to develop a method for quickly identifying light intensity peak in an active alignment process.

- Parts to be aligned include Photonic ICs, Laser diodes, Lenses, Fibers, etc.

- Use a fast active alignment method to achieve both cost reduction and throughput improvement over the current active alignment methods used.

- Improved adhesion speed of parts after alignment. Adhesives should preferentially be UV cured or thermoset.

- Adhesive should have minimal shrinkage after curing.

Possible Solution Areas

High-speed assembly technology for:

- Optical communication devices

- Semiconductor post-process

- MEMS

And:

- Adhesive or material makers

- Alignment equipment

Desired Outcome of the Solution

Looking for partners to make the technology.

Field of Use and Intended Applications

rapid assembly of optical communication devices

Previously Attempted Solutions

Commonly used conventional technologies such as active alignment method by using monitoring the light intensity.

Related Tech Needs

Seeking: Improving Solder Joints and Solder-Bonded Chips

Seeking: Technologies to Improve Flip-Chip Bonding Accuracy

Seeking: Tech to ID Early-Stage Failure of Optical Components

Seeking: High Frequency Test for Optical Communications Devices